Process standardisation

Manual General Visual Inspections (GVIs) vary between technicians and shifts, leading to variabilities in the inspection process, results, and quality.

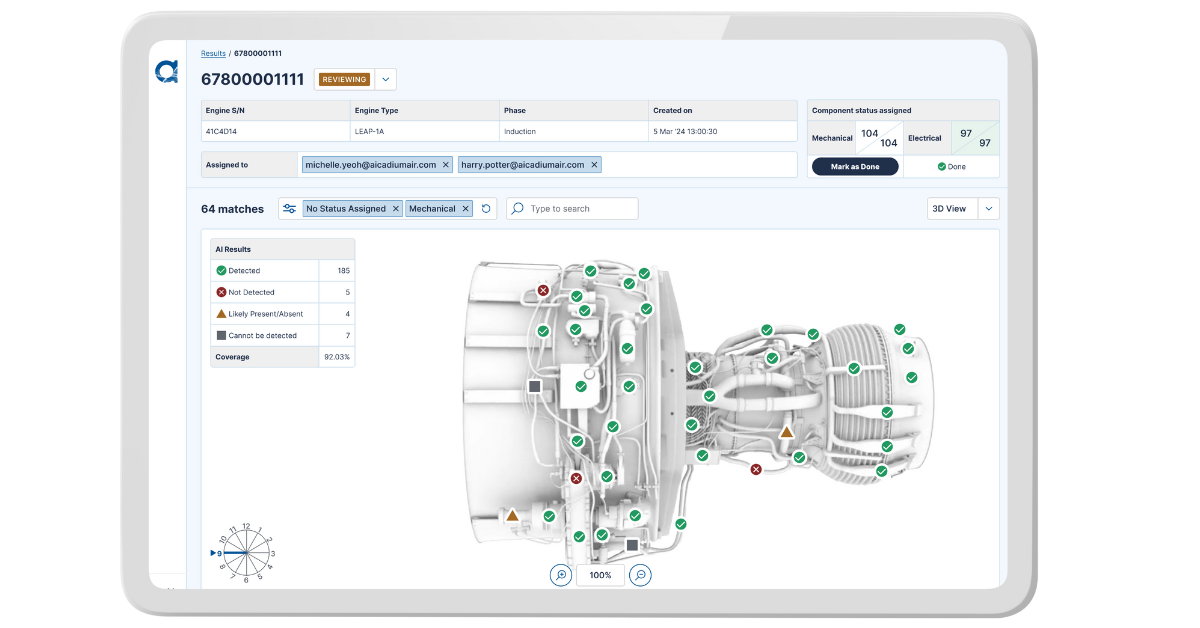

Harness the power of AI to revolutionise engine inspections, build standardised inspection workflows, drive workforce efficiency, and provide full visual traceability.

Challenges MROs are facing today

Manual General Visual Inspections (GVIs) vary between technicians and shifts, leading to variabilities in the inspection process, results, and quality.

Without structured digital visual records, it's difficult to audit past inspections, verify quality, or ensure accountability. This creates blind spots that limit transparency and make it harder to resolve disputes or improve processes.

Missed defects, foreign object debris, or mismatched components due to human oversight can lead to costly rework, extended turnaround times, and lost customer trust

Our solution acts as a co-pilot for technicians, improving accuracy, reducing manual workload, and ensuring compliance.

Purpose-built handheld device enables high-quality, guided image capture in areas where fixed setups are impractical, such as in tight engine bays, line maintenance zones or field operations. Designed for ease of use, minimal training, and consistent coverage, even by non-experts.

Automatically assists with detections of missing parts, possibilities of surface defects and foreign object debris (FOD), reducing inspection variability and improving issue detection accuracy.

Aids component verification links visual identification of serial and part numbers with digital inventory records, enabling seamless traceability and faster discrepancy detection.

Generates consistent, audit-ready inspection reports with all findings, detection results and metadata - reducing documentation effort and review cycles.

Compares captured data against golden sample references to verify part presence and installed statuses during induction and dispatch phases, accelerating inventory and quality checks.

Leverages inspector feedback to improve detection performance over time - enabling smarter, more efficient inspections with every use.

Each inspection is logged with image evidence, timestamps, detection results, and user activity - supporting auditability and quality review.

Supports integration with robotic and handheld devices to streamline inspections in both structured and space-constrained environments, without the need for additional infrastructure.

.png)

Integrates smoothly with any or existing image capturing solutions, with no need for additional procurement.

Ensures data protection with end-to-end encryption and full compliance with industry safety and data privacy standards.